workshop & studio

nearly 100% of production is in house

We utilize every inch of our 2,500 sq ft space efficiently by keeping equipment & work areas mobile.This conserves space & keeps our overhead costs low that we pass on to you.We use the latest tools & fabrication techniques & invent our own tools when necessary to stay one step ahead of the competition.

woodworking

Woodwork is a staple of the industry, and is a main focus of our business.We have highly skilled craftsman & some of the best tools to fabricate your project.We can handle oversize sheet stock & cut materials up to 4" thick.We know the proper woods, joinery, and assembly to build stage flats to fit & finishing the finest furniture.

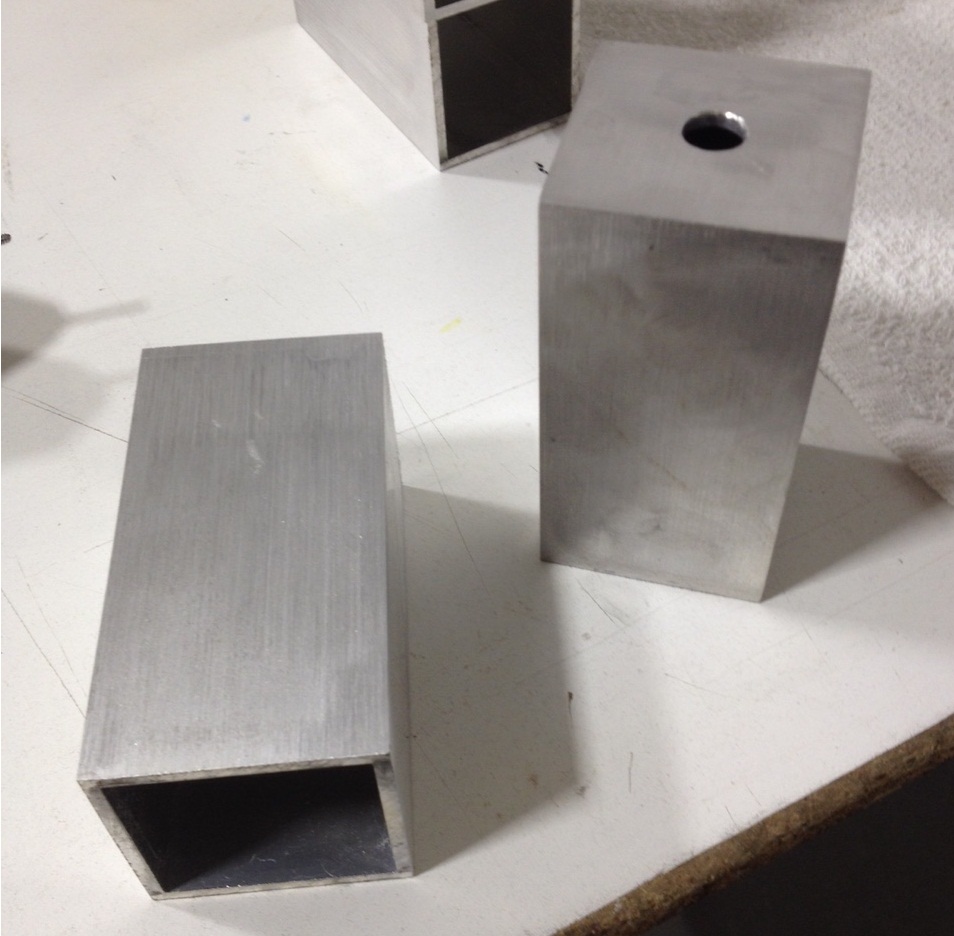

Metalworking

Metal work is a key component of custom fabrication.Our metal shop includes cutting, bending, rolling, polishing, milling, turning & welding.If we can't make the metal parts economically in house, we will do the research and have it made.We were asked to provide thin metal sculptures etched in delicate .025" polished brass.After cross country research & many phone calls, we were able to find a etcher with high tech equipment who could, get the special material and complete the 200 parts with 20 different designs in 3 weeks.

casting

"Cold Casting" is the process of pouring a liquid plastic resin into a mold and allowing it to harden generally at room temperature. There are many types of resins available from soft foam & rubbers, to hard plastics. All of these can be color matched to your specification.

Some specialty resins need more complex processing such as heat cycling, and others must be placed in a special tank under pressure to harden such as Crystal Clear resins that are often used to encapsulate objects. These are more costly to produce.

Overmolding

We invented a process to increase casting time for small parts. We overmolded 380 joints for metal headphone wire used in a prototype display for Apple. Turnaround time for the parts was 24 hours to make the master shapes, clear molds & parts. The idea was borrowed from the Stereolithography process that uses UV light to cure plastic resin in just seconds. We made molds out of clear silicone so the resin inside the mold could be cured by the light. UV resin was injected into the mold around the wire, and cured instantly.

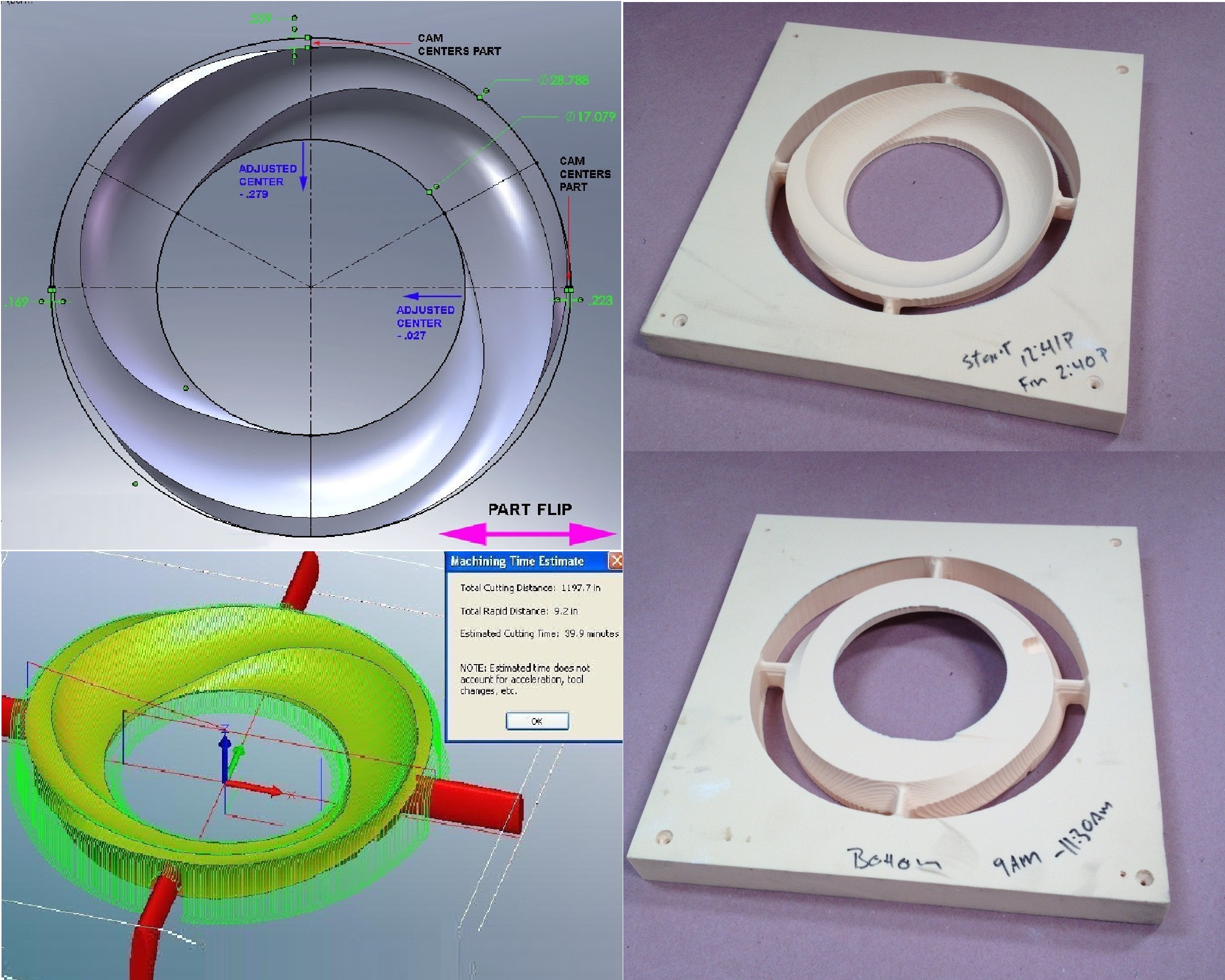

CNC Milling

Our capability to machine 2D sheets & 3D shapes from computer models allows us to save time and reproduce parts with great accuracy. We can cut Metals, Plastics & Structural Foams with ease. This Möbius shape was machined to match on 2 sides. we built a small test model, then the 3ft diameter finished shape. Send us your CAD files or have us design them for you.